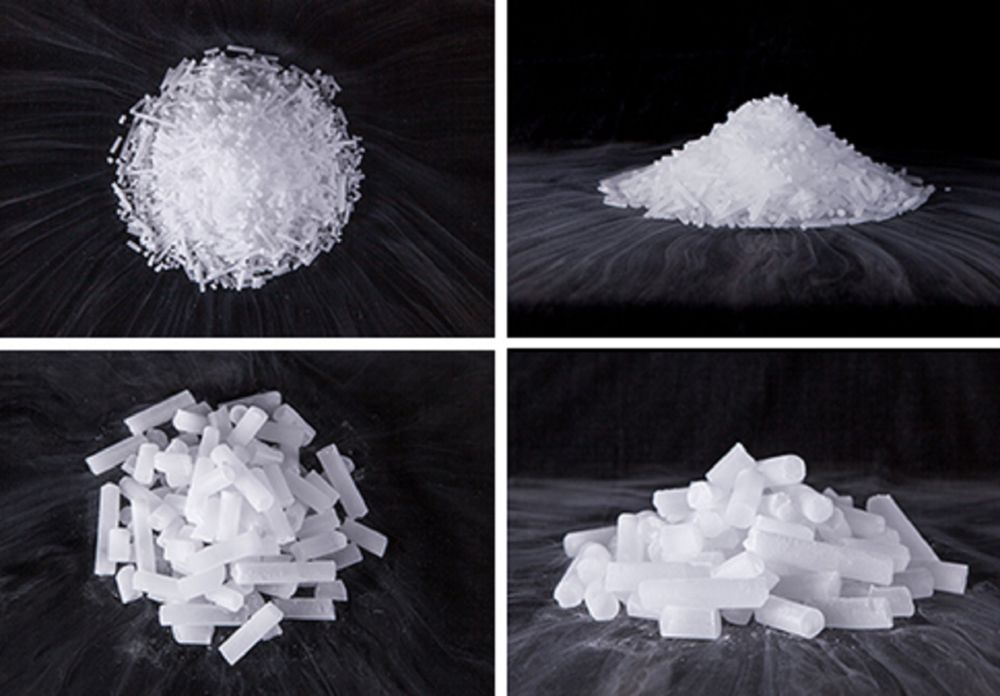

Dry ice is a multifaceted cooling agent that does not turn into water, but sublimates into a gaseous state. Its temperature of -78.48°C is close to Antarctic records!

It turns out that due to its amazing physical properties, dry ice in pellet form is an ideal cleaning agent that works well in industry to remove contaminants from sensitive tools and equipment.

The dry ice cleaning process uses granules that strike the selected item, thereby causing a sudden, spot cooling of the coating or dirt you plan to remove. Due to their high kinetic energy, dry ice pellets not only deform and crush – they also create micro-fractures in the dirt layer as they impact the workpiece. The dry ice particles then enter and increase their volume up to 1000 times to separate the unwanted layer from the selected surface.

The medium used throughout the procedure changes to a gaseous state. Unlike most traditional techniques, dry ice cleaning is not an abrasive process. No scratches or wear appear on the surface.

What makes customers more and more willing to opt for dry ice cleaning?

Dry ice cleaning allows for simultaneous application in several objects with different geometries, therefore the technology is most often used to remove contaminants from plastic and rubber molds. It is also great for degreasing surfaces, which is why it is successfully used in the food, wood and paper industries. It can also be used to remove paint or corrosion.

In order for dry ice to retain its valuable properties, it must be stored properly. The best protection is an insulated container:

The thick insulation helps slow the rate of dry ice (CO2) sublimation that leads to expansion or rupture of the container. Be sure to keep the container in a well-ventilated area.

The dry ice temperature is -78.5oC.

No. Dry ice cleaning is done under high pressure. When dry ice particles hit the surface to be cleaned, they change their state of aggregation from solid to gaseous. They take up about 600-800 times the surface area, bursting the dirt from the inside. This is an abrasion-free method, so it does not adversely affect the condition of the surface.

The great advantage of this method is that dry ice does not generate waste. It turns into a gas and evaporates. All that remains is the dirt from the application being cleaned.

Standard for about 3-4 days. However, it should be taken into account that in unfavorable weather conditions (e.g. high humidity) it may sublimate faster.

The machine operator should wear eye protection (goggles, visor), hearing protection (protective headphones, earplugs) and gloves for working with low temperatures. The room where the process is carried out should be ventilated to avoid the accumulation of dangerous amounts of CO2.

Yes. EMTECH IPH GROUP offers special dry ice machines that can run on a continuous supply of dry ice cubes or pellets straight from the dry ice maker.